Custom Dental Prosthetics with 3D Printing have revolutionized the dental industry. This innovative approach provides numerous advantages over traditional methods. From enhanced precision to cost-efficient solutions, it’s a game-changer.

3D printing technology allows for the creation of highly precise, customized dental prosthetics. It ensures a perfect fit for each patient, leading to increased comfort and satisfaction. We’ll delve into how this technology works and its myriad benefits.

In this article, we’ll explore essential tips for designing custom dental prosthetics using 3D printing. We’ll also highlight the key advantages that make this method a preferred choice for many dental professionals.

Understanding Custom Dental Prosthetics with 3D Printing

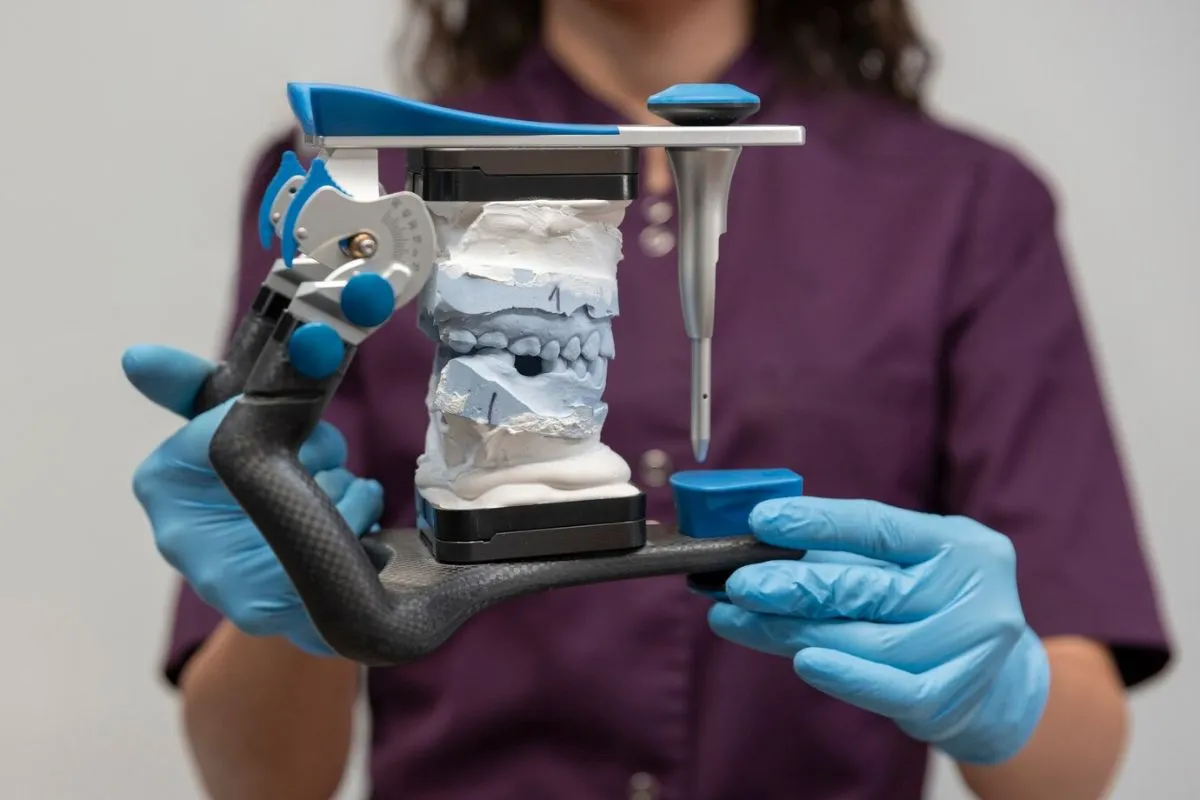

Custom dental prosthetics created through 3D printing involve a digital workflow. It starts with scanning the patient’s mouth to create a digital model. This model forms the basis for the design of the prosthetic.

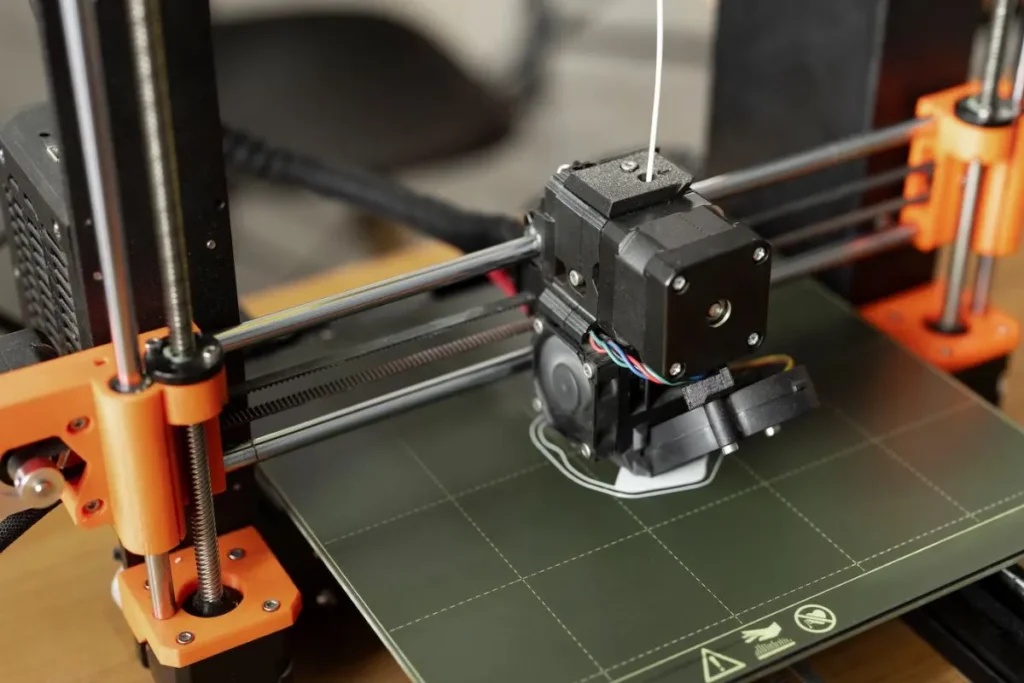

Once the digital design is finalized, it’s fed into a 3D printer. The printer uses various materials, often biocompatible, to build the prosthetic layer by layer. This technique ensures precision that is hard to achieve with traditional methods.

Furthermore, the entire process is swift. From design to final product, 3D printing significantly reduces the time required compared to traditional manufacturing techniques.

Advantages of Custom Dental Prosthetics with 3D Printing

Using 3D printing technology for custom dental prosthetics offers multiple advantages. These include:

- Precision: High accuracy in prosthetic design and fit.

- Comfort: Personalized fit leads to better patient comfort.

- Durability: Materials used are often more durable.

- Cost-effective: Reduced material wastage and labor costs.

Precision and Accuracy

One of the standout benefits of 3D printing in this context is the precision. By leveraging digital scans of the patient’s mouth, the prosthetic can be designed to fit perfectly. This leads to a significant increase in comfort for the patient.

Traditional methods often involve multiple fittings and adjustments. This not only prolongs the process but can also be uncomfortable for the patient. 3D printing mitigates these issues by getting it right the first time.

The digital technology used also allows for real-time adjustments. This means that any necessary tweaks can be made quickly and accurately, ensuring an optimal fit.

Comfort and Patient Satisfaction

Custom dental prosthetics are designed to fit precisely in the patient’s mouth. This high level of customization results in increased comfort. Patients often report higher satisfaction levels compared to traditional prosthetics.

Additionally, the digital workflow of 3D printing means that any discomfort can be addressed swiftly. Adjustments can be made seamlessly without the need for new molds or extensive manual rework.

This leads to a smoother overall experience for patients, reducing anxiety and making dental prosthetics more accessible and appealing.

Durability and Longevity

The materials used in 3D printing are typically more durable than those used in traditional prosthetics. This results in longer-lasting dental solutions. Patients benefit from prosthetics that stay intact and functional for extended periods.

This durability also means fewer replacements and repairs. It’s a significant advantage in terms of both cost and convenience for patients and dental professionals alike.

Moreover, the accuracy of the fit provided by 3D printing reduces the wear and tear on the prosthetic, prolonging its lifespan.

Cost-Effectiveness

Traditional dental prosthetics can be expensive, both in terms of materials and labor. 3D printing offers a cost-effective alternative by minimizing waste and reducing the need for manual labor.

Additionally, the rapid production times associated with 3D printing mean that dental practices can serve more patients in less time. This efficiency translates to cost savings that can be passed on to the patient.

The initial investment in 3D printing technology is often offset by these long-term savings, making it a financially viable option for many dental practices.

Tips for Designing Custom Dental Prosthetics with 3D Printing

Start with a High-Quality Scan

The foundation of a perfect custom dental prosthetic lies in a high-quality digital scan. Using advanced intraoral scanners ensures that the digital model is accurate and detailed.

Make sure the scan captures all necessary details, including the patient’s bite and surrounding oral structures. This precision is crucial for designing a prosthetic that fits perfectly.

Invest in the latest scanning technology and ensure that your team is well-trained in its use to get the best results.

Utilize Advanced Design Software

The design software you use can greatly impact the quality of the final custom dental prosthetic. Invest in advanced software that offers robust features for detailed and accurate design work.

This software should allow for easy modifications and adjustments to the digital model. It’s also beneficial if the software integrates seamlessly with your 3D printing hardware.

Regularly update the software and train your team to utilize all available features for optimal results.

Choose the Right Materials

The choice of materials is critical in the durability and comfort of the custom dental prosthetic. Biocompatible materials are often preferred as they’re safe for long-term use in the mouth.

The material should also be durable and resistant to wear and tear. This ensures the prosthetic has a longer lifespan and requires fewer adjustments.

Consult with your material suppliers to stay updated on the latest innovations and choose the best options for your patients.

Future of Custom Dental Prosthetics with 3D Printing

Technological Advancements

The field of 3D printing is constantly evolving, with new advancements promising even greater precision and efficiency. Future technologies may enable even more complex and customized dental prosthetics.

Artificial intelligence (AI) and machine learning (ML) are poised to play significant roles in this evolution. They could further streamline the design and production process, making it even more efficient.

Staying updated with these advancements ensures that your dental practice remains at the forefront of innovation.

Increased Accessibility

As 3D printing technology becomes more widespread, the cost of equipment and materials is expected to decrease. This will make custom dental prosthetics more accessible to a larger population.

Lower costs will also enable smaller dental practices to adopt this technology. This means more patients can benefit from the enhanced comfort and precision offered by custom dental prosthetics.

This democratization of access is a promising trend in the dental industry, ensuring that more people can receive high-quality dental care.

Environmental Impact

Using 3D printing for custom dental prosthetics can also have a positive environmental impact. This technology often uses fewer materials and generates less waste compared to traditional manufacturing.

Sustainable materials are also being developed for use in 3D printing, further reducing the environmental footprint. By adopting these practices, dental professionals can contribute to a more sustainable future.

Considering these environmental benefits is another reason to embrace 3D printing technology in your dental practice.

Looking Forward to a Brighter Future

The integration of custom dental prosthetics with 3D printing offers a glimpse into the future of dental care. With advancements in technology, we can expect even greater improvements in precision, comfort, and accessibility.

For dental professionals, staying updated with these developments is crucial. Embracing this technology not only enhances patient care but also sets your practice apart as a leader in innovation.

As the field continues to evolve, the possibilities for improved dental care are limitless. Investing in 3D printing today is investing in the future of dentistry.

Frequently Asked Questions

What is the main benefit of custom dental prosthetics with 3D printing?

The main benefit is the high precision, ensuring a perfect fit and greater comfort for the patient.

How does 3D printing improve the process of creating dental prosthetics?

3D printing streamlines the process, reduces production time, and ensures a higher level of accuracy than traditional methods.

Are 3D printed dental prosthetics more expensive?

While the initial investment in technology is high, the overall process is more cost-effective due to reduced material waste and labor costs.

What materials are used in 3D printed dental prosthetics?

Biocompatible materials are commonly used, which are safe for long-term use in the mouth and are durable.

What role does digital technology play in 3D printed dental prosthetics?

Digital technology ensures precise design and real-time adjustments, enhancing the accuracy and fit of the custom prosthetic.