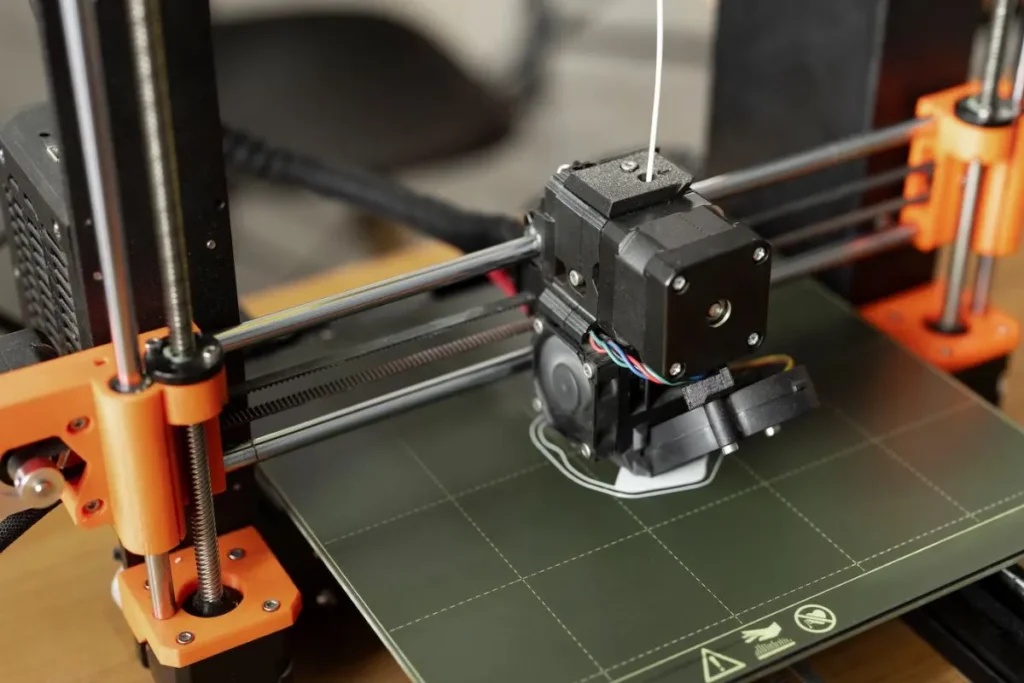

Exploring creative uses for 3D printed flexible circuits opens up a world of possibilities in modern engineering and design. With advancements in 3D printing technology, flexible circuits are becoming a game-changer. In this article, we delve into innovative applications and projects using this cutting-edge technology.

As the field of 3D printing evolves, flexible circuits are emerging as a popular choice for diverse applications. From wearable technology to medical devices, the potential seems limitless. Here, we outline some key tips and projects to inspire your next innovation.

Incorporating 3D printed flexible circuits into your work can enhance the functionality and aesthetics of your designs. We will explore the benefits, provide practical tips, and discuss various use cases where these circuits shine. Whether you’re an engineer, a designer, or just a tech enthusiast, there’s something here for you.

The Rise of 3D Printed Flexible Circuits

The rise of 3D printed flexible circuits in the technology landscape is closely tied to advancements in printing techniques. These circuits offer flexibility and adaptability. They can conform to complex shapes, making them ideal for innovative engineering solutions.

Traditional rigid circuits are limited by their inflexibility. Flexible circuits, however, can be integrated into products in unique ways. This adaptability is beneficial for modern design requirements. Moreover, the compatibility with various substrates enhances their usability.

As more industries adopt 3D printing, the production of flexible circuits is becoming more streamlined. This means faster prototyping and custom manufacturing. Such flexibility is crucial in today’s fast-paced development environments.

Why Choose Flexible Circuits?

Flexible circuits offer several advantages over conventional rigid circuits. Their ability to bend, twist, and fold without breaking makes them suitable for dynamic applications. This means designers have more freedom in product development.

In addition to mechanical flexibility, they are often more durable under stress. This reliability is essential for high-stakes applications like medical devices and aerospace components. Flexible circuits are also lighter, which can be an asset in weight-sensitive designs.

Another key advantage is the potential for reducing assembly costs. Integrating a flexible circuit can minimize the need for connectors and interconnections. This simplification can lead to more efficient manufacturing processes and reduced labor costs.

Innovative Applications

Creative uses for 3D printed flexible circuits span multiple industries. Let’s explore some groundbreaking applications where these circuits are making a significant impact. These examples showcase the versatility and innovation that flexible circuits bring to the table.

In wearable technology, flexible circuits play a pivotal role. They can be embedded into fabrics, enabling smart clothing that monitors health metrics. Similarly, in the sports industry, smart textiles can track performance and provide real-time feedback.

The medical field also benefits immensely. Flexible circuits are used in advanced prosthetics to provide better control and functionality. They are also found in wearable health monitors, offering non-intrusive patient care.

Wearable Technology

Wearable technology is one of the primary beneficiaries of flexible circuits. Their ability to conform to the human body allows for seamless integration into clothing and accessories. This opens up possibilities for health and fitness tracking.

Smart watches and fitness bands are common examples. These devices use flexible circuits to wrap around wrists comfortably while providing continuous monitoring. More advanced options include smart shirts that can track heart rate and posture.

Virtual reality (VR) and augmented reality (AR) devices also leverage flexible circuits. These circuits contribute to lightweight and comfortable designs, enhancing the user experience. Innovations in this area are continually pushing the boundaries of what is possible.

Medical Devices

In medical devices, flexible circuits enable sophisticated functionalities. They are crucial in creating advanced prosthetics that mimic natural movements. These circuits provide the necessary electrical pathways in compact and flexible designs.

Wearable health monitors are another critical application. Flexible circuits make it possible to create non-intrusive devices. These devices can track vital signs, assist in remote patient monitoring, and improve overall healthcare.

Beyond prosthetics and monitors, medical sensors benefit from this technology. Flexible circuits allow for sensors that can adapt to various body parts. This leads to better measurements and more effective treatment plans.

Tips for Successful Implementation

For those looking to implement 3D printed flexible circuits, a few key tips can guide successful projects. Proper planning and design consideration are crucial. Here, we cover essential aspects to keep in mind.

Material selection is one of the first steps. The right substrate can impact flexibility and durability. Materials like polyimide and polyethylene terephthalate are common choices for their excellent properties.

Also, understanding design limitations is vital. While flexible circuits offer many advantages, they come with unique constraints. Ensuring compatibility with the intended application is essential for maximizing benefits.

Material Selection

The choice of material for flexible circuits can greatly affect their performance. Polyimide is a popular choice due to its heat resistance and flexibility. This material can withstand the stresses associated with bending and twisting.

Polyethylene terephthalate (PET) is another excellent option. It offers good flexibility and is cost-effective. PET is particularly useful for applications where cost is a critical factor.

Thermoplastic polyurethane (TPU) is used when transparency is needed. It’s also highly flexible and durable. Understanding the specific requirements of your project will guide material selection.

Design Considerations

Careful design planning is vital for flexible circuits. One significant aspect is ensuring that the circuit layout minimizes stress points. This involves optimizing trace routing to prevent failure due to bending.

Thermal management should also be considered. Flexible circuits can experience thermal stress, impacting performance. Implementing proper heat dissipation strategies ensures reliability.

Furthermore, connector reliability is crucial. Using robust connectors that can withstand repeated flexing will improve the lifespan of the circuit. Designing with these considerations in mind will lead to more successful implementations.

Prototyping and Manufacturing

Prototyping of flexible circuits has become more accessible thanks to 3D printing. Rapid prototyping allows for quick iterations and testing. This is invaluable for refining designs before moving to production.

During the manufacturing phase, maintaining consistency is key. Quality control measures should be implemented to ensure each circuit meets specifications. This helps in avoiding performance issues down the line.

Additionally, collaboration with experts in flexible circuit design can enhance outcomes. Leveraging specialized knowledge ensures best practices are followed. This can lead to more innovative and reliable final products.

Rapid Prototyping

Rapid prototyping is enabled using advanced 3D printing techniques. This allows for faster iterations. Designers can quickly test and refine their ideas.

3D printing makes it possible to create complex geometries. These geometries would be challenging to achieve with traditional methods. This capability is especially beneficial for custom and bespoke designs.

The ability to iterate quickly reduces time to market. Projects can move from concept to production much faster. This speed is a critical advantage in competitive industries.

Manufacturing Best Practices

Ensuring quality control is vital during the manufacturing process. Each circuit must meet defined specifications. This maintains consistency and reliability.

Testing each unit thoroughly is essential. This helps identify any potential issues early. Comprehensive testing protocols ensure that the final product performs as expected.

Collaboration with experts can also enhance manufacturing outcomes. Working with professionals familiar with flexible circuits ensures that best practices are followed. This leads to higher-quality and more innovative products.

Conclusion and Future Prospects

Creative uses for 3D printed flexible circuits continue to evolve. They are revolutionizing industries from healthcare to consumer electronics. The integration of these circuits is paving the way for new innovations.

As 3D printing and material science advance, even more exciting applications will emerge. Engineers and designers have a unique opportunity. They can leverage these advancements to push the boundaries of what’s possible.

By staying informed about the latest developments, you can harness the full potential of flexible circuits. Whether it’s for a new project or to enhance an existing one, the possibilities are endless.

Ready to explore the limitless potential of 3D printed flexible circuits? Start incorporating this technology into your designs and see the transformative impact it can have. The future is flexible, and the future is now.

Frequently Asked Questions

What are flexible circuits?

Flexible circuits are electronic circuits that can bend and twist, making them suitable for various dynamic applications. They are often used in wearable technology, medical devices, and complex designs.

Why use 3D printing for flexible circuits?

3D printing allows for rapid prototyping and custom designs. It can create complex geometries that are difficult to achieve with traditional methods. This makes it ideal for flexible circuits that require precise and unique shapes.

What materials are best for flexible circuits?

Common materials for flexible circuits include polyimide, polyethylene terephthalate (PET), and thermoplastic polyurethane (TPU). Each material offers different properties, such as heat resistance, flexibility, and transparency.

What are some creative uses for 3D printed flexible circuits?

There are many creative uses for 3D printed flexible circuits, including smart textiles, advanced prosthetics, and wearable health monitors. They are also used in VR/AR devices and aerospace components.

How can I ensure the reliability of flexible circuits?

To ensure reliability, focus on proper material selection, careful design planning, and thorough testing. Using robust connectors and implementing thermal management strategies can also improve performance and longevity.