Using Carbon Fiber Composites in 3D Printing is revolutionizing the manufacturing industry. This innovative approach combines lightweight materials with high strength and durability. Let’s delve into its advancements and applications.

The integration of carbon fiber into 3D printing has opened new possibilities. Prototyping and production of complex parts are now more efficient. Such composites offer unmatched robustness.

Industries are rapidly adopting these techniques. We will explore how Using Carbon Fiber Composites in 3D Printing is changing various sectors. The focus will be on its properties and benefits.

Advancements in Carbon Fiber Composites

Enhanced Material Properties

Carbon fiber composites are known for their superior performance. These materials exhibit high tensile strength and low weight. They are ideal for applications demanding durability.

Incorporating carbon fiber into 3D printing boosts the material’s structural integrity. This combination offers exceptional performance in load-bearing applications. It ensures long-term reliability.

People are continually seeking stronger and lighter materials. Carbon fiber composites meet these needs perfectly. They have revolutionized various manufacturing processes.

Material Composition

Carbon fiber is composed mainly of carbon atoms. These atoms are arranged in a crystalline structure. The resulting material is extremely strong.

Composites are formed by combining carbon fiber with other materials. These can include resins or plastics. The process results in a material with enhanced characteristics.

This composition provides significant advantages. The composites are not only strong but also lightweight. They resist various environmental stressors.

3D Printing Technology Integration

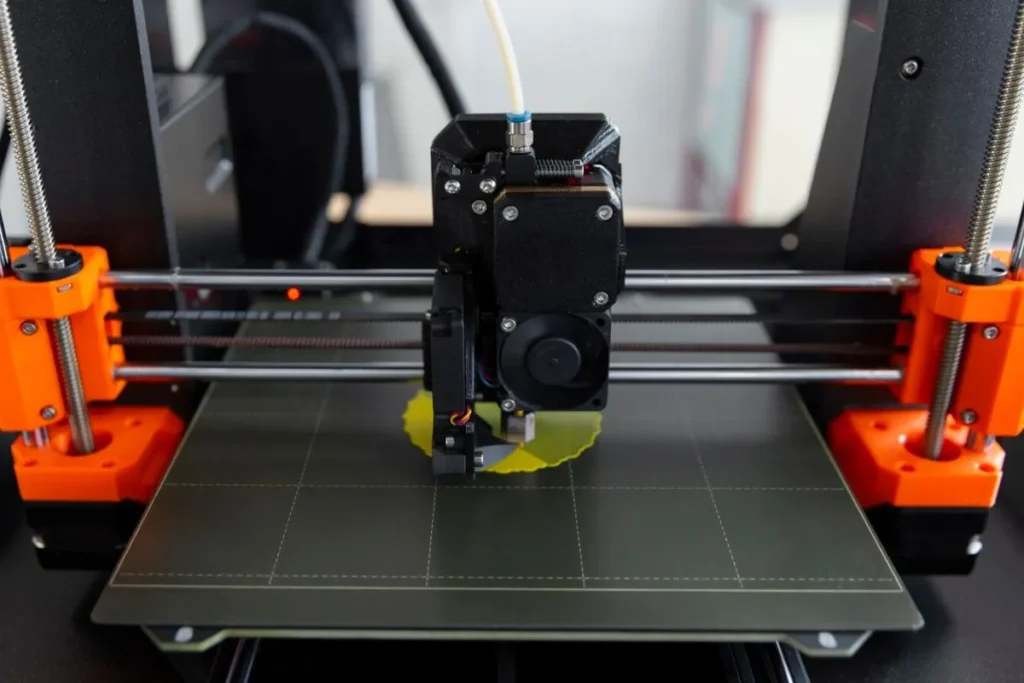

The integration of carbon fiber composites has pushed the boundaries of 3D printing. Additive manufacturing can now produce stronger and more durable parts. It ensures high-quality outputs.

Advanced 3D printers can print carbon fiber composites. These printers have specialized nozzles and extruders. They handle the composite materials efficiently.

The result is a seamless printing process. Manufacturers can produce complex parts with great accuracy. This technology integration is a game-changer.

Bullet points for critical printers:

- Printers with heated beds

- Specialized nozzles for carbon fiber

- Advanced software for design optimization

Technological Improvements

Technological advancements are continuously improving. Newer printers are more capable and versatile. They offer higher precision and speed.

These enhancements are vital in various industries. They enable the production of more complex and efficient parts. The automotive and aerospace sectors particularly benefit.

Future advancements will further streamline 3D printing. They will lead to even better integration of composite materials. This progression is inevitable.

Applications of Carbon Fiber Composites

Aerospace Industry

The aerospace industry greatly benefits from Using Carbon Fiber Composites in 3D Printing. These materials offer high strength to weight ratios. They ensure the construction of lighter and stronger components.

Aircraft parts made from carbon fiber composites are more durable. They reduce the overall weight of the aircraft. This results in better fuel efficiency.

The durability of these parts ensures extended life cycles. Maintenance and replacement frequency are reduced. This is crucial in the high-stakes aerospace industry.

Innovative Components

Carbon fiber composites are used to create novel aerospace components. These include wings, fuselage parts, and brackets. These innovations enhance performance.

3D printing enables the production of complex geometries. Parts are optimized for maximum efficiency. This degree of customization is unprecedented.

The aerospace sector continues to embrace these advancements. Future aerospace designs will be more integrated with carbon fiber composites. The trend is here to stay.

Automotive Industry

The automotive industry is another significant beneficiary. Using Carbon Fiber Composites in 3D Printing provides unmatched durability. It also contributes to weight reduction.

Components such as chassis and body parts use carbon fiber composites. These parts provide strength while keeping vehicles light. It improves performance and fuel efficiency.

Manufacturers can design and prototype faster. The versatility of 3D printing is a crucial advantage. It speeds up the development cycle significantly.

Performance Enhancements

Carbon fiber composites enhance vehicle performance. Lighter components reduce strain on engines. Vehicles can achieve higher speeds and better handling.

Durability ensures a long lifespan for critical components. This reduces long-term maintenance costs. Vehicle reliability is improved.

The automotive sector is increasingly reliant on these advancements. Carbon fiber composites are the future of automobile manufacturing. This trend will continue to grow.

Prototyping and Custom Manufacturing

Prototyping is significantly improved with Using Carbon Fiber Composites in 3D Printing. Manufacturers can create functional prototypes quickly. This speeds up the design and testing phases.

Custom manufacturing is more feasible. Carbon fiber composites allow for tailored solutions. Products can be customized to exact specifications.

3D printing with carbon fiber is ideal for low-volume manufacturing. It reduces costs and time associated with traditional methods. Production processes are more streamlined.

Tailored Solutions

Custom solutions are a major benefit. Businesses can address niche markets. Products are designed for specific needs.

Carbon fiber composites provide flexibility in manufacturing. Businesses can adapt quickly to market changes. This is essential for staying competitive.

Industries across the board value this adaptability. Custom manufacturing with 3D printing is increasingly popular. It’s transforming how products are developed.

Future Prospects

Continuous Improvement

The future of Using Carbon Fiber Composites in 3D Printing looks promising. Continuous advancements are on the horizon. These will further enhance material properties.

New composites will be developed. These will offer even greater strength and durability. The possibilities are endless.

Research into these materials is ongoing. Breakthroughs will continue to emerge. The technology will keep evolving.

Industry Collaboration

Collaboration across industries will drive innovation. Shared expertise leads to new applications. This synergy benefits all sectors involved.

Joint research initiatives are crucial. They push the boundaries of what is possible. Partnerships will yield significant advancements.

The collective effort ensures rapid progress. Industries working together will achieve more. The future is collaborative.

Broader Applications

The applications of carbon fiber composites will expand. New markets will emerge. These materials will be ubiquitous.

Construction and healthcare are potential growth areas. The benefits of carbon fiber are universally appealing. Many sectors stand to gain.

Innovation will know no bounds. The versatility of these materials will be fully realized. We are on the cusp of a materials revolution.

The Future of Additive Manufacturing

Using Carbon Fiber Composites in 3D Printing is setting new industry standards. This technology offers substantial benefits in strength, durability, and lightweight properties.

The potential applications are vast, from aerospace to custom manufacturing. This versatility ensures continued growth and innovation. It’s clear that carbon fiber composites are here to stay.

As technology advances, the integration of carbon fiber in 3D printing will increase. Businesses and industries will need to stay abreast of these changes. For the latest updates and insights, stay connected.

Frequently Asked Questions

How durable are carbon fiber composites in 3D printing?

Carbon fiber composites in 3D printing offer high durability. They combine strength with resistance to wear and tear. These properties extend the lifespan of printed parts.

Can carbon fiber composites be used in all types of 3D printers?

Not all 3D printers can handle carbon fiber composites. Specialized printers with specific nozzles and heated beds are required. These printers ensure the proper extrusion of composite materials.

What industries benefit the most from using carbon fiber composites in 3D printing?

The aerospace and automotive industries benefit significantly. These sectors require high-strength, lightweight materials. Carbon fiber composites are also useful in prototyping and custom manufacturing.

Are there any limitations to using carbon fiber composites in 3D printing?

One limitation is the cost of materials and technology. Carbon fiber composites and specialized 3D printers can be expensive. However, these costs are offset by the durability and performance of the printed parts.

What future advancements can we expect in this field?

Future advancements will enhance the properties of carbon fiber composites. Continuous improvement in 3D printing technology will also occur. Broader applications across various industries are expected.