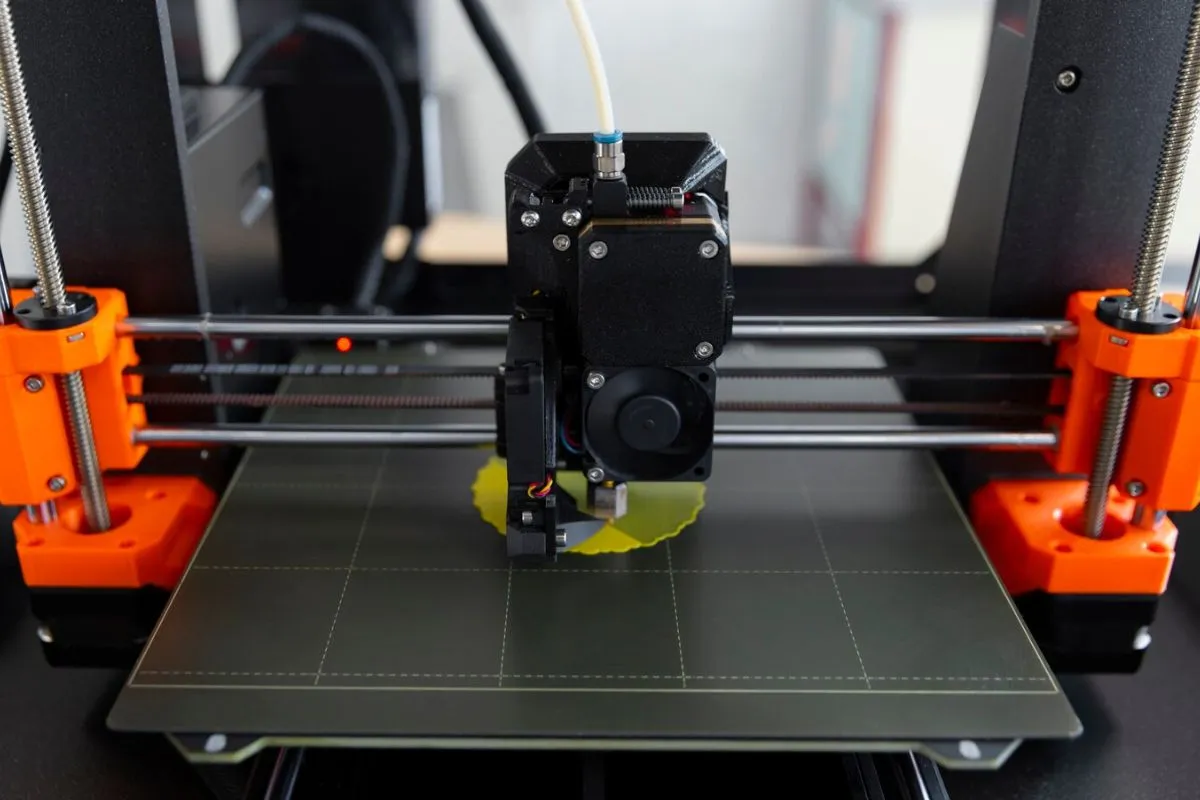

Conductive Filaments for 3D Printed Electronics are revolutionizing the way we design and manufacture electronic devices. These filaments enable the integration of complex circuits directly into 3D printed objects. With the increasing demand for rapid prototyping, conductive filaments have become vital for creating functional devices.

This article explores Conductive Filaments for 3D Printed Electronics, their properties, and methods for utilizing them effectively. We will delve into their applications across various industries and how they enhance additive manufacturing processes.

Understanding the different types of Conductive Filaments available today can optimize your 3D printing projects. Discover the potential these materials hold and how they can be leveraged for innovative electronic designs.

Types of Conductive Filaments

There are several types of Conductive Filaments available, each offering unique properties for different applications. Conductive polymers are flexible and easy to print, making them suitable for wearable electronics. Metal-infused filaments provide higher conductivity and are ideal for circuits and sensors. Nanomaterial-based filaments, such as those containing graphene, offer exceptional conductivity and strength.

The most commonly used types include conductive polymers, metal-infused filaments, and nanomaterial-based filaments. Conductive polymers are often used in flexible electronics due to their pliability. Metal-infused filaments, which combine metals like copper or silver with a plastic base, are used where higher electrical conductivity is required.

Nanomaterial-based filaments leverage advanced materials like carbon nanotubes or graphene, providing superior electrical properties and mechanical strength for high-performance applications.

Conductive Polymers

Conductive polymers are plastics that contain carbon or other conductive particles.

These polymers are flexible, lightweight, and can be easily incorporated into various designs. They are popular for creating flexible circuits and wearables.

Metal-Infused Filaments

Metal-infused filaments blend metal particles with standard 3D printing materials. These filaments offer higher conductivity compared to polymers but can be more brittle.

They are suitable for creating robust electronic connections and components.

Nanomaterial-Based Filaments

Nanomaterial-based filaments integrate materials like graphene or carbon nanotubes. These filaments provide high conductivity and strength, making them ideal for advanced electronic applications. Their use is growing in industries requiring precision and durability.

Methods for Using Conductive Filaments

Integrating Conductive Filaments into 3D printing processes requires specific methods and techniques.

Understanding these methods ensures the effective creation of electronic components and devices.

Designing Circuits

Designing circuits with Conductive Filaments involves careful planning and software use. CAD tools can help design intricate patterns and paths for electronic components within a 3D printed object.

Printing Techniques

Printing techniques vary based on the filament type and desired outcome. For conductive polymers, standard FDM (Fused Deposition Modeling) printers suffice, while metal-infused and nanomaterial-based filaments may require specialized equipment.

Post-Processing

Post-processing steps are crucial for ensuring the conductivity and performance of printed circuits. Steps may include curing, sintering, or additional coatings to enhance conductivity and durability.

Applications of Conductive Filaments

Wearable Electronics

Wearable electronics benefit from the flexibility and lightweight nature of conductive polymers. They are used to create smart textiles, health monitors, and other wearable devices integrated directly into clothing and accessories.

Prototyping and Development

Conductive Filaments facilitate rapid prototyping for electronic components. Inventors and engineers use them for developing and testing new devices quickly and cost-effectively, accelerating the innovation process.

Educational Tools

Educational institutions use 3D printing with conductive filaments to teach students about circuitry and electronics. These hands-on experiences help students understand complex concepts through interactive learning.

Challenges and Future Directions

While Conductive Filaments offer numerous advantages, they also present challenges. Addressing these challenges is crucial for advancing their applications and capabilities in 3D printing. One significant challenge is achieving consistent conductivity throughout the printed object.

Material cost and availability can also be limiting factors, making it essential to find cost-effective solutions. Moreover, optimizing printer settings for different filament types requires ongoing research and development. Overcoming these obstacles will pave the way for broader adoption and innovative uses of conductive filaments.

Conductivity and Durability

Ensuring consistent conductivity and durability can be challenging with certain filament types. Ongoing research aims to improve these properties, especially for applications requiring high performance and reliability.

Material Costs and Availability

The cost and availability of various Conductive Filaments can be limiting factors. As demand grows, economies of scale and material innovations are expected to reduce costs and expand availability.

Standardization and Compatibility

Standardization efforts are needed to ensure compatibility between different filament types and 3D printing technologies. Establishing industry standards will facilitate wider adoption and integration of conductive filaments in electronic designs.

Future Trends in Conductive Filaments

Integration with IoT

Integration with the Internet of Things (IoT) is a significant trend for Conductive Filaments. As more devices become interconnected, the need for custom, 3D printed electronics will grow, driving innovation in this field.

Bioelectronics

Bioelectronics is another area poised to benefit from Conductive Filaments. Research focuses on creating biodegradable and biocompatible filaments for medical applications, including implants and diagnostic devices.

Advanced Manufacturing Techniques

Advanced manufacturing techniques, such as multi-material 3D printing, are expanding the capabilities of conductive filaments.

These techniques enable the creation of complex, multi-functional devices in a single print, paving the way for innovative electronic solutions.

Investing in Conductive Filaments

Investing in Conductive Filaments for 3D Printed Electronics opens up numerous opportunities for businesses and individuals. Understanding the potential and challenges can guide informed decisions in this growing field.

Industry Collaboration

Industry collaboration is vital for advancing the use of Conductive Filaments. Partnerships between material scientists, engineers, and manufacturers can drive innovation and overcome existing challenges.

Educational Programs

Educational programs focusing on 3D printing and conducting materials are essential for training the next generation of engineers and designers. These programs can foster creativity and practical knowledge, leading to new applications and innovations.

Research and Development Investment

Investing in research and development is crucial for the advancement of Conductive Filaments. Funding innovative projects and supporting research initiatives can lead to breakthrough discoveries and expanded applications.

Key Takeaways

Conductive Filaments for 3D Printed Electronics are transforming the creation of electronic devices. Their versatility and potential are enhancing additive manufacturing and rapid prototyping.

Challenges such as conductivity, durability, cost, and standardization need to be addressed. Collaborative efforts within the industry and continued research are essential for overcoming these challenges.

Investments in education, research, and industry partnerships will drive the future of Conductive Filaments. As technology advances, the applications of these materials will continue to grow, shaping the future of electronics and manufacturing.

Exploring and investing in Conductive Filaments can provide a competitive edge in the rapidly evolving field of 3D printing and electronics. Stay informed about the latest developments and consider how these innovative materials can benefit your projects and business.

Frequently Asked Questions

What are conductive filaments?

Conductive filaments are 3D printing materials designed to conduct electricity, enabling the creation of electronic components directly within 3D printed objects.

Which industries benefit from conductive filaments?

Industries such as wearables, prototyping, education, and bioelectronics benefit from conductive filaments due to their versatility and ability to customize electronic designs.

Can standard 3D printers use conductive filaments?

Standard FDM printers can use conductive polymers, while metal-infused and nanomaterial-based filaments may require specialized equipment for optimal results.

What are the main challenges of using conductive filaments?

Challenges include ensuring consistent conductivity, durability, managing costs, and achieving standardization across different filament types and printing technologies.

How do conductive filaments enhance rapid prototyping?

Conductive filaments enable rapid prototyping by allowing quick and cost-effective development of functional electronic components and devices within 3D printed objects.