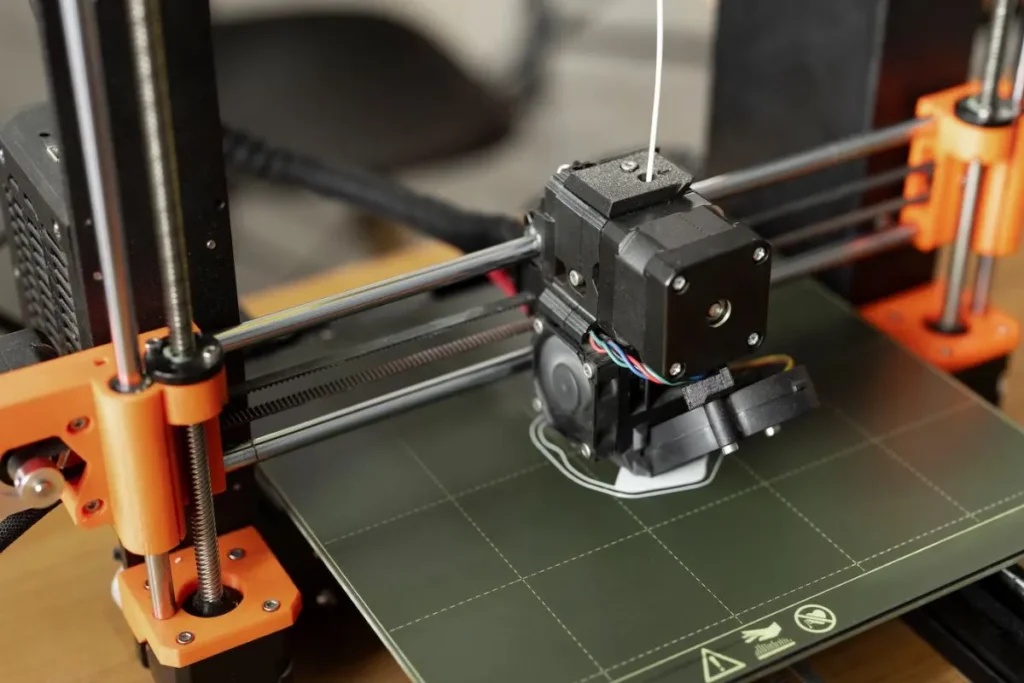

Using AR with 3D Printing for Prototyping is revolutionizing product development. The synergy between these technologies enables more effective and efficient prototyping.

This article explores key tips and examples for leveraging augmented reality (AR) alongside 3D printing. Discover how these tools transform the creative process and digital manufacturing.

Advantages of Using AR with 3D Printing for Prototyping

Using AR with 3D Printing for Prototyping offers several benefits. It enhances design precision and enables faster iterations.

AR can overlay digital models onto physical spaces, aiding visual clarity. This integration can streamline the workflow, reducing costs and time.

Additionally, combining these technologies fosters innovation and creativity. Teams can quickly explore different design concepts in a tangible manner.

Enhancing Design Precision

AR supports designers in visualizing complex geometries. Combining AR with 3D printing ensures that models match real-world dimensions accurately.

This combination helps identify potential design issues early. By overlaying digital designs onto the physical prototype, adjustments can be made with great precision.

Ultimately, this minimizes material waste and optimizes the use of resources during prototyping.

Speeding Up Iterations

An efficient prototyping process involves rapid cycles of feedback and revision. Using AR with 3D Printing for Prototyping significantly accelerates these cycles.

Design teams can visualize and modify their prototypes in real-time. This immediate feedback loop shortens the overall development timeline.

By integrating AR and 3D printing, developers can swiftly iterate and refine their concepts before final production.

Enabling Creative Exploration

The fusion of AR and 3D printing unlocks new creative potential. Designers can experiment with different forms and functionalities easily.

This blend supports a hands-on creative process where virtual and physical elements interact seamlessly. The tangible nature of 3D prints complements the visual dynamism of AR models.

This approach encourages innovative thinking and problem-solving within the design team.

Examples of Using AR with 3D Printing in Prototyping

Several industries are leveraging Using AR with 3D Printing for Prototyping. Here are some practical examples demonstrating their application:

In the automotive sector, AR is used to visualize assembly parts. Coupled with 3D printing, teams can quickly prototype and validate automotive components.

The healthcare industry benefits from AR and 3D printing for surgical planning. Surgeons can visualize patient-specific anatomy and create accurate 3D models for practice.

Case Study: Automotive Industry

Ferrari, a leading automotive manufacturer, uses Using AR with 3D Printing for Prototyping. AR helps engineers visualize modifications within the car’s real-world context.

This integration allows rapid testing and validation of new parts. 3D printed components can be fitted and evaluated quickly, speeding up the innovation process.

Such an approach ensures that new designs meet performance and quality standards.

Case Study: Healthcare Applications

The healthcare sector is seeing transformative changes with Using AR with 3D Printing for Prototyping. Surgeons and medical professionals use AR to overlay patient anatomy for surgical planning.

3D printing provides patient-specific models for practice and simulation. This ensures higher precision during actual surgical procedures.

By combining AR and 3D printing, the medical field can reduce risks and improve patient outcomes.

Architectural Design

Architects use AR to overlay virtual designs onto physical spaces. Paired with 3D printing, this approach allows for tangible scale models.

Clients can visualize and interact with these models in AR. This offers a better understanding of the design concept.

Integrating these technologies streamlines client approvals and enhances design communication.

Implementation Tips for Combining AR and 3D Printing

To maximize the benefits of Using AR with 3D Printing for Prototyping, follow these tips:

Choose suitable AR software that integrates well with your 3D printing system. Ensure the software supports file formats used in 3D printing.

Involve your design team early in experimenting with these tools. Collaboration is key to exploring the full potential of AR and 3D printing.

Choosing the Right Tools

Selecting the appropriate tools is crucial. Look for AR platforms that are compatible with your existing design software.

Consider the hardware capabilities of your 3D printer. Different printers support various resolution and material types.

A good match between the software and hardware will enhance your prototyping process significantly.

Collaborative Efforts

Encourage teamwork and collaboration in your design process. Using AR and 3D printing together requires interdisciplinary expertise.

Designers, engineers, and project managers should work closely. Regular brainstorming sessions can spark innovative ideas.

This holistic approach ensures that the creative process benefits from diverse perspectives.

Iterative Development

Prototyping is inherently an iterative process. Leverage the rapid feedback loop enabled by AR and 3D printing.

Constantly test and refine your designs. Use AR to visualize changes in real-time and 3D print prototypes for tangible validation.

This cycle of continuous improvement accelerates product development and reduces time-to-market.

Augmented Reality Tools for 3D Printing Prototyping

Several AR tools are specifically designed to aid prototyping with 3D printing. Here are some popular options:

WakingApp

WakingApp offers a user-friendly interface for creating AR experiences. It supports various file types via plugins.

It’s ideal for designers looking to integrate AR easily. Coupled with a versatile 3D printer, it reflects designs with precision.

Daqri

Daqri is an industrial-grade AR tool supporting complex prototyping needs. It provides exceptional visualization capabilities, ideal for engineering applications.

Combining Daqri with 3D printing enhances the modeling process significantly. Its high accuracy ensures precise representations of design concepts.

ARKit by Apple

ARKit is another powerful AR tool suitable for various prototyping applications. Compatible with iOS devices, it’s accessible to a broad audience.

Pairing ARKit with a reliable 3D printer enables efficient design processes. It offers extensive features for interactive and immersive experiences.

Future of Prototyping with AR and 3D Printing

Looking forward, the integration of AR with 3D Printing for Prototyping is poised to advance further. Emerging technologies and software upgrades will make this synergy even more potent.

Developments in material science will enhance 3D printing capabilities. At the same time, AR software will become more intuitive and user-friendly.

This evolution will create new opportunities for innovation and digital manufacturing.

Emerging Technologies

Technologies like AI and machine learning will play essential roles. These will support automated design suggestions and improvements.

Smart materials will expand the possibilities of 3D printing. Combined with AR, this will result in more sophisticated and functional prototypes.

Overall, the future holds exciting prospects for prototyping using these technologies.

Software Advancements

AR software will continue to evolve, becoming more robust and feature-rich. This will include better integration with 3D printing tools and enhanced user interfaces.

These advancements will lower the barrier for entry, making these technologies accessible to a wider range of industries.

By simplifying the user experience, more innovators can contribute to digital manufacturing advancements.

New Use Cases

As these technologies evolve, new use cases will emerge. Education, retail, and other sectors will find unique applications for AR with 3D printing.

Educators can use these tools to create interactive learning experiences. Retailers can offer personalized product designs and visualizations.

Such innovations will drive the adoption and evolution of prototyping methods.

Engage with Future Innovations

In summary, Using AR with 3D Printing for Prototyping offers transformative potential. It enhances design precision, speeds up iterations, and encourages creative exploration.

As we look to the future, staying updated with emerging technologies is crucial. Engage with these innovations to stay ahead in the competitive landscape.

Start experimenting with AR and 3D printing now to unlock the full potential of prototyping creativity!

Frequently Asked Questions

What are the main benefits of using AR with 3D printing for prototyping?

It increases design precision, speeds up iterations, and fosters creativity. The combination also reduces costs and material waste.

Which industries benefit the most from AR and 3D printing?

Industries like automotive, healthcare, and architecture utilize these technologies. They improve product development, surgical planning, and design communication.

Can AR tools be used with any 3D printer?

Not all AR tools are compatible with every 3D printer. Ensure the software supports the file formats and resolution of your 3D printer.

How does AR help in the prototyping process?

AR overlays digital designs onto physical prototypes, enhancing visualization. This helps identify issues and visualize modifications in real-time.

What should I consider when choosing AR tools for 3D printing?

Consider compatibility with existing software, support for various file formats, and ease of use. Evaluate the specific needs of your prototyping process.