Architectural Models Made with 3D Printing offer a revolutionary approach to modern design. These models enhance visualization and allow architects to experiment with innovative ideas.

The fusion of 3D printing and architecture brings about breakthroughs in construction techniques. This innovation opens doors to an era where architectural dreams can materialize quickly.

As technology advances, using Architectural Models Made with 3D Printing becomes more sophisticated. This article explores methods and inspirations behind this cutting-edge practice.

The Evolution of Architectural Models

From Traditional Methods to Modern Technology

Traditional architectural models were often painstakingly crafted by hand. These models, though detailed, required significant time and resources. Advances in technology have drastically reduced these constraints.

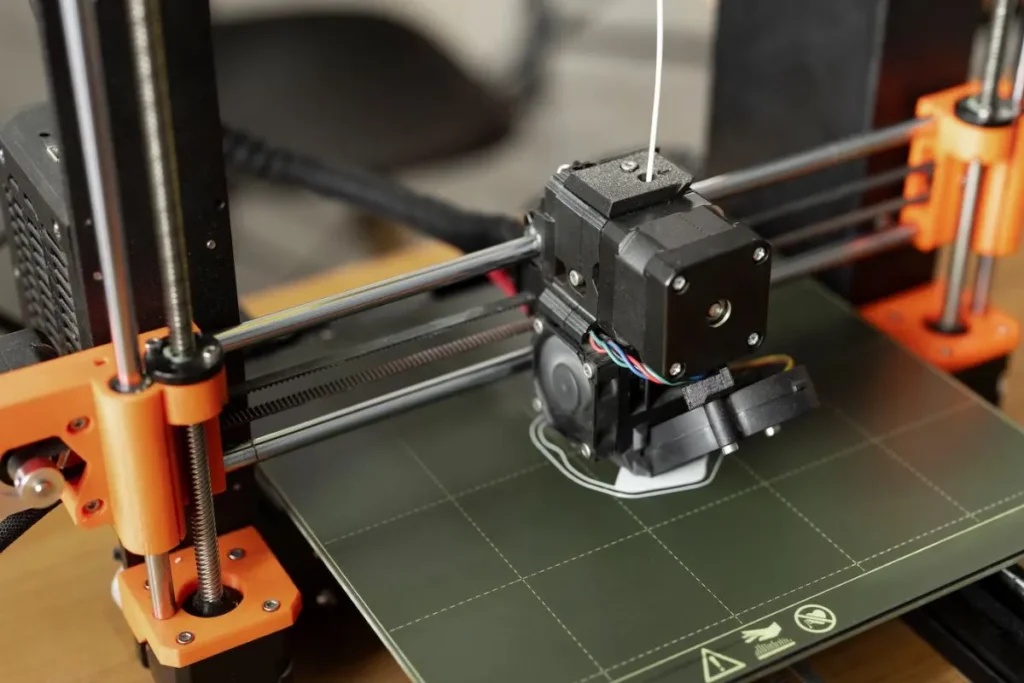

Now, 3D printing technology revolutionizes model creation. Precision and efficiency grow as CAD software and 3D printers handle complex designs effortlessly.

The use of 3D printing in architecture represents a shift toward combining creativity with precision. This balance leads to more accurate and adaptable architectural plans.

Materials in 3D Printed Architectural Models

Various materials contribute to the effectiveness of 3D printed models. Choices range from plastics to advanced composite materials, each offering unique properties.

PLA and ABS plastics are common due to their accessibility and ease. However, more sophisticated materials like resins and composites enhance detail and durability.

The choice of material often depends on the model’s purpose. Temporary demonstrations may use basic plastics, while permanent, durable models might incorporate metal or advanced composites.

The Role of CAD Software

CAD software is crucial in the creation of Architectural Models Made with 3D Printing. Programs like AutoCAD and Rhino allow architects to design precise digital blueprints.

These digital designs enable detailed customization, ensuring every aspect of the model aligns with the architectural vision. CAD also supports complex geometries, which are hard to achieve manually.

The integration of CAD software with 3D printing ensures that models are not only accurate but also realistic. This synergy revolutionizes how we visualize future architectural projects.

Innovative Methods in 3D Printing

Layering and Additive Manufacturing

3D printing operates on an additive manufacturing principle. Layers of material are deposited sequentially, shaping the complex architectural model.

This method allows for the creation of intricate designs with minimal material waste. Unlike traditional methods, additive manufacturing can build structures with internal support and detail.

Such innovation results in stronger, lighter models that perfectly represent the desired architectural elements. This efficiency marks a significant leap over older subtractive methods.

Simulation of Real-World Conditions

Architectural Models Made with 3D Printing often simulate real-world conditions, aiding in environmental analysis. This simulation helps understand how designs react to various factors, improving their resiliency.

Architects can analyze elements like wind flow, sunlight, and thermal properties. These insights lead to more sustainable and functional designs.

Incorporating these factors into the design phase ensures that the final construction is environmentally efficient and aligned with real-world demands.

Inspiration from Nature

Architects draw inspiration from nature to create innovative models. Bio mimicry integrates natural forms and processes into design, improving functionality and aesthetics.

For example, studying the structure of leaves can inspire ventilation systems, while examining honeycombs can inspire efficient space usage.

3D printing allows these natural inspirations to manifest in tangible models. This interdisciplinary approach merges art and science, leading to progressive architectural designs.

Case Studies in 3D Printed Architectural Models

Urban Planning and Large-Scale Models

Architectural Models Made with 3D Printing are highly significant in urban planning. Large-scale models provide a comprehensive view of city projects.

These models help visualize the impact of new developments on existing infrastructures and communities. They play crucial roles in stakeholder engagement and public consultations.

Cities like Singapore have utilized 3D printed models for their Smart Nation initiative. These models aid in urban planning, making the process more interactive and inclusive.

Modern Architectural Marvels

Modern architecture often pushes the boundaries of design. Projects like Zaha Hadid’s designs exemplify using 3D printing to create futuristic and avant-garde structures.

The curves and fluid forms in Hadid’s works are ideal for 3D printing, which allows the creation of complex geometries that traditional methods can’t achieve.

These models offer insight into construction feasibility, embracing the potential of printing technology to realize challenging architectural visions.

Sustainable Architecture

Sustainability is a critical factor in modern architecture. 3D printing aids in creating eco-friendly buildings, prioritizing minimal environmental impact.

Materials such as biodegradable plastics and recycled composites are used to meet green standards. This approach ensures that designs are both innovative and sustainable.

Sustainable architectural models crafted by 3D printing showcase how future constructions can harmonize with the environment. This practice sets a new standard for industries worldwide.

Benefits and Challenges of 3D Printed Architectural Models

Enhanced Visualization

Architectural Models Made with 3D Printing significantly enhance visualization. They offer a tangible representation of projects, aiding in more effective communication.

Clients and stakeholders can better understand and engage with the design, leading to more informed decisions. This visual clarity reduces misunderstandings and aligns expectations.

The ability to see and touch a model ensures that potential issues are identified and addressed early in the design process. This proactive approach saves time and resources.

Cost and Time Efficiency

3D printing accelerates the model creation process, saving valuable time. Traditional methods often involve prolonged timelines and labor-intensive processes.

By contrast, 3D printing achieves precision rapidly, streamlining workflows. Materials are utilized efficiently, reducing overall costs.

This efficiency allows architects to explore multiple iterations and refinements without significant delays or expenses. The result is a more polished and accurate final model.

Technical Limitations

Despite its advantages, 3D printing faces technical limitations. Material choices and printer capabilities can restrict the intricacy and scale of models.

Advanced projects might demand materials that current printers can’t handle. Additionally, there are constraints on the size of printable objects, impacting larger designs.

Continuous advancements in 3D printing technology aim to overcome these challenges. Emerging innovations promise to broaden the possibilities for architectural models.

Future Perspectives of 3D Printed Architectural Models

The future of Architectural Models Made with 3D Printing is promising. As technology evolves, so will the capabilities and applications of these models.

Potential developments include the use of advanced materials and smarter, more efficient printers. This future innovation will further integrate with sustainable practices.

3D printed models are set to play a pivotal role in shaping the future of architecture. They offer a blend of creativity, precision, and sustainability that aligns with modern construction demands.

Frequently Asked Questions

How accurate are 3D printed architectural models?

They are highly accurate, thanks to precise CAD designs and advanced 3D printing technology. This accuracy ensures detailed and realistic representations.

Can 3D printing be used for full-scale construction?

Yes, some projects already use 3D printing for actual building elements. This is an emerging field aiming to revolutionize traditional construction methods.

What materials are commonly used in 3D printed architectural models?

Common materials include PLA, ABS plastics, resins, and sometimes metal composites. The choice depends on the model’s purpose and required durability.

How does 3D printing impact project timelines?

It significantly reduces timelines by speeding up the model creation process. This efficiency allows quicker iterations and refinements, enhancing project management.

Is 3D printing environmentally friendly?

It can be. Using biodegradable and recycled materials promotes sustainability. Additionally, 3D printing minimizes waste compared to traditional subtractive methods.