3D Printing with Biodegradable Materials represents a leap forward in sustainable manufacturing. This technique combines advanced technology with eco-friendly materials.

Through innovative methods, it aims to reduce environmental impact and promote a circular economy. These advancements are reshaping the future of additive manufacturing.

In this article, we will explore methods and applications of 3D printing with biodegradable materials. We will delve into the technology behind it and its benefits for sustainability.

Understanding 3D Printing with Biodegradable Materials

3D printing, also known as additive manufacturing, involves creating objects layer by layer. When combined with biodegradable materials, it becomes a powerful tool for sustainability.

Biodegradable materials decompose naturally and minimize waste. These materials include PLA (polylactic acid) and PHA (polyhydroxyalkanoates). They are derived from renewable sources like corn or sugarcane.

The use of such materials in 3D printing addresses environmental concerns. It offers a way to create products that are both functional and eco-friendly.

The Emergence of Eco-Friendly 3D Printing

The integration of 3D printing with biodegradable materials is relatively new. The innovation in materials science has enabled the development of eco-friendly 3D printing solutions.

This technology is now accessible to both industries and hobbyists. It provides a means to produce high-quality, sustainable products at lower costs.

Companies are increasingly adopting these methods to promote sustainable manufacturing practices. This shift is driven by the growing demand for eco-friendly products.

Benefits of Using Biodegradable Materials

There are numerous benefits to using biodegradable materials in 3D printing. Here are some key advantages:

- Environmental Impact: Reduces plastic waste and lowers carbon footprint.

- Sustainability: Supports the circular economy by using renewable resources.

- Recyclability: The materials can be easily recycled or composted.

- Innovation: Encourages the development of new materials and applications.

These benefits highlight the importance of transitioning to biodegradable materials. By doing so, we can create a more sustainable future.

Methods of 3D Printing with Biodegradable Materials

There are various methods of 3D printing using biodegradable materials. Each method has its unique advantages and applications. Here are some commonly used methods:

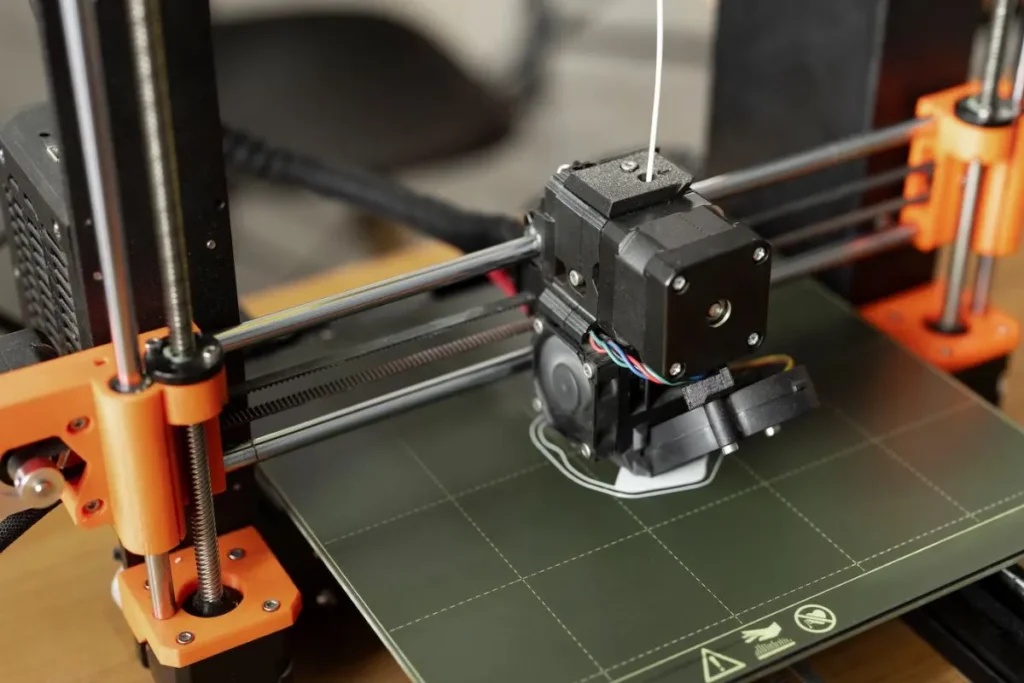

Fused Deposition Modeling (FDM)

FDM is one of the most widely used 3D printing techniques. It involves the extrusion of thermoplastic material layer by layer.

Biodegradable filaments like PLA are commonly used in FDM. This method is ideal for creating detailed and precise objects.

FDM is popular for its simplicity and cost-effectiveness. It is often used for prototyping and small-scale production.

Stereolithography (SLA)

SLA uses a laser to cure liquid resin into solid objects. This method offers high resolution and exceptional surface finish.

Biodegradable resins are being developed for use in SLA. They provide the same benefits as traditional resins but with less environmental impact.

SLA is suitable for applications that require intricate designs and smooth surfaces. It is commonly used in industries like dentistry and jewelry.

Selective Laser Sintering (SLS)

SLS utilizes a laser to fuse powdered material into solid shapes. It can produce complex geometries and functional prototypes.

Biodegradable powders are now being explored for SLS. These materials offer the potential for sustainable manufacturing.

SLS is favored for its ability to create durable and functional parts. It is used in aerospace, automotive, and consumer product industries.

Applications of 3D Printing with Biodegradable Materials

The applications of 3D printing with biodegradable materials are vast. This technology is transforming various sectors. Here are some notable applications:

Healthcare

In healthcare, 3D printing is used to create custom medical devices. Biodegradable materials are ideal for temporary implants and surgical tools.

This method allows for personalized solutions tailored to individual patients. It enhances the overall quality of medical care.

Biodegradable 3D-printed scaffolds are used in tissue engineering. They support cell growth and gradually dissolve as the tissue regenerates.

Consumer Goods

The consumer goods industry benefits significantly from 3D printing. Biodegradable materials enable the production of eco-friendly products.

This includes items like toys, household items, and wearable accessories. These products can be customized to meet consumer preferences.

Using biodegradable materials aligns with the growing trend of sustainability. It appeals to environmentally conscious consumers.

Packaging

Packaging is another sector where 3D printing with biodegradable materials is making an impact. It offers sustainable alternatives to traditional packaging.

This technology allows for the creation of custom, one-of-a-kind packaging solutions. It can reduce material waste and improve product protection.

Biodegradable packaging is compostable, reducing the burden on landfills. It supports a circular economy by closing the loop on waste.

Future Prospects of 3D Printing with Biodegradable Materials

The future of 3D printing with biodegradable materials looks promising. As technology evolves, new materials and methods will emerge.

Researchers are exploring innovative compounds to enhance biodegradability. This will expand the range of applications and improve performance.

Industries are likely to adopt these technologies more widely. This will drive a shift towards sustainable manufacturing practices globally.

Environmental Impact and Circular Economy

3D printing with biodegradable materials significantly reduces environmental impact. It minimizes waste and promotes resource efficiency.

Adopting these methods aligns with the principles of the circular economy. It encourages recycling and the use of renewable resources.

This approach is essential for achieving long-term sustainability goals. It contributes to reducing the carbon footprint of manufacturing processes.

Challenges and Opportunities

Despite the benefits, there are challenges to overcome. The cost of biodegradable materials can be higher compared to standard plastics.

There is also a need for more research on biodegradable filaments. Ensuring consistent quality and performance is crucial.

However, these challenges present opportunities for innovation. Advances in materials science and economies of scale will drive costs down.

Industry Collaboration and Innovation

Collaboration between industry leaders and researchers is key. Joint efforts can accelerate the development of new materials and technologies.

Open-source platforms and shared knowledge can foster innovation. This collective approach can address existing challenges effectively.

By working together, we can usher in a new era of sustainable manufacturing. The potential for positive environmental impact is immense.

A Brighter Future with Biodegradable 3D Printing

3D Printing with Biodegradable Materials is shaping a sustainable future. The technology’s benefits for the environment and manufacturing are evident.

Adopting these methods will significantly reduce waste and carbon footprint. It aligns with global efforts to promote a circular economy.

Investing in research and collaboration is key. These steps will ensure the continued advancement of eco-friendly 3D printing solutions.

Frequently Asked Questions

What are biodegradable materials?

Biodegradable materials are substances that can decompose naturally. They break down into non-toxic components through biological processes.

How does 3D printing with biodegradable materials work?

3D Printing with Biodegradable Materials involves using eco-friendly filaments or powders. These materials are extruded or cured to create solid objects layer by layer.

What are the advantages of using biodegradable materials in 3D printing?

Advantages include reduced environmental impact, support for the circular economy, and the ability to create recyclable and compostable products.

Which industries benefit from 3D printing with biodegradable materials?

Industries such as healthcare, consumer goods, and packaging benefit greatly. They use this technology to create eco-friendly, high-quality products.

What are the future prospects of biodegradable 3D printing?

The future is promising with ongoing research and development. New materials and methods will expand applications and improve performance.